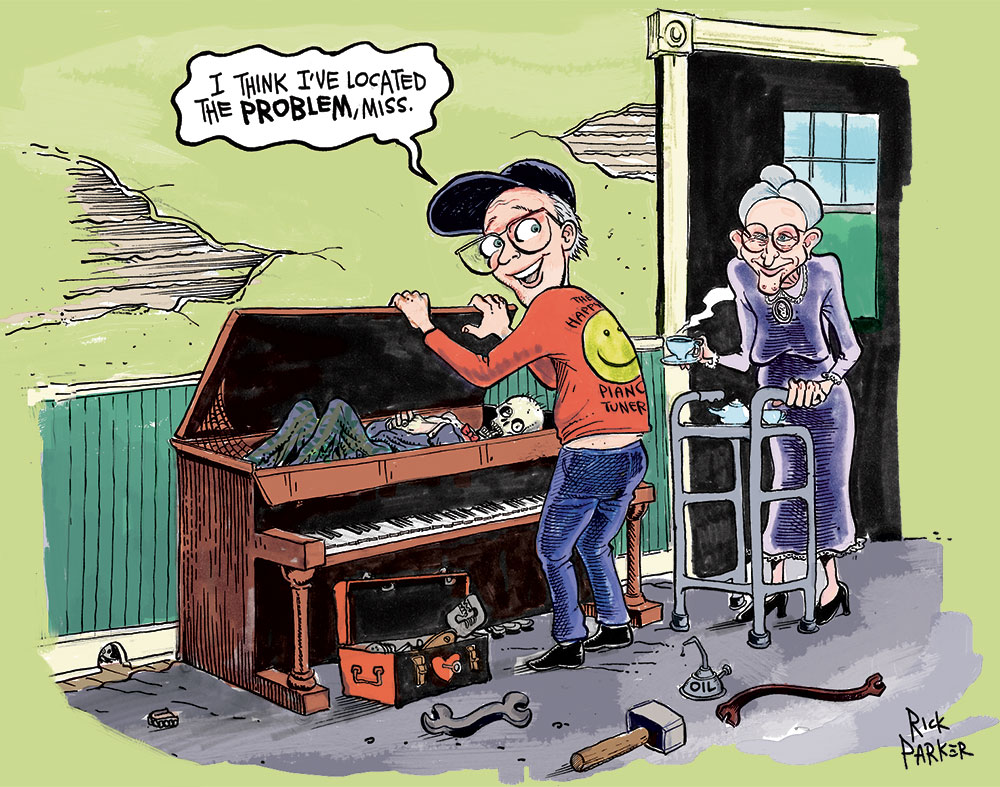

Why Bad Things Happen to Good Pianos

A cracked soundboard (the thin board stretched across the frame of a piano whose role is to amplify sound) seems to be everyone’s greatest fear. It is generally caused by dryness, age and stress. It can be sealed to stop the buzzing, but to cosmetically repair, the strings must be removed and the crack must be shimmed and re-lacquered.

The following causes a rattling sound:

Loose hammer heads (felt mallet which makes contact with string for sound)

Loose pedal rods

Cracked bridge/loose bridge pins (Strings rest against the bridge to transmit sound to the soundboard.)

Damper felt has become hard (Dampers rest on strings to stop ringing; lifts when keys are depressed.)

Cracked soundboard (the thin board stretched across the frame of a piano whose role is to amplify sound)

Cracked bridge/loose bridge pins (Strings rest against the bridge to transmit sound to the soundboard)

Loose case hardware/objects outside of piano (i.e. lamps, etc.) I call these “pathetic” vibrations.

Objects lying on a grand piano soundboard (i.e. pennies and loose crews)

Key centers too tight

Flange pins too tight

Hammers (felt mallets which makes contact with string for sound) rubbing on each other

Rust

Loose tuning pins (strings are mounted on tuning pins, which are tightened and loosened for pitch)

Uneven tension across bass and treble bridges

Frequent changes in temperature and humidity, too close to windows, heaters and air conditioners

Constant heavy use

Moving the piano

Sticking Keys

Poor tuning (pins not set properly)

Cracked pin block (a rack maple laminated plank holding the tuning pins) this cannot be repaired and must be replaced, which is quite expensive

Uprights: Tack carpeting to back of piano

Place piano on thick carpeting or rug

Open bottom board and place one or two pillows inside (not to obstruct pedals)

Voicing down hammer volume (This manipulates tone by hardening or softening felt)

Grands: Place piano on heavy carpet

Mount piano on heavy rubber pedestals

Tack foam and fabric under soundboard

Voicing down hammers

Hammers (felt mallets which makes contact with string for sound) work, need shaping (sanding grooves from hammer heads) or replacing (included in maintenance package)

Hammers are hard, need voicing (manipulates tone by hardening or softening felt) This is also included in maintenance package.

“Jingling”—strings buzzing on the harp

Bushings (felt leather, teflon cushion around pin) worn

Needs lubrication

Case screws need tightening

All of the above are included in maintenance package.

Center rail bushings (felt leather, teflon cushion around pin) have collapsed and need leveling

Ivories chipped or missing

Note: Ivories can be replaced, but matching color is difficult.

Damper felt is hard

Dampers are not aligned to string

Note: The top two octaves do not have dampers, so they always ring.